LED Panel | Pros and Cons of Edge-Lit and Back-Lit

July 02, 2024

The LED pane is commonly available on the market. Based on its structural principle, these lights can be divided into two types: edge-lit and back-lit. Both work on the same principle: to produce luminous lighting by driving the power supply through voltage and current to the LED chips. They differ in their product structure, light form, and luminous principle.

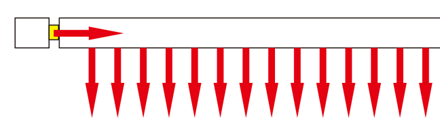

The edge-lit LED panel has a luminous structure, as shown in Figure 1. The LED chip emits light that enters the LGP from the side and is then released onto the panel's surface through the LGP.

Figure 1

The edge-lit LED panel have several advantages (pros) this way:

1. The panel's height can be made smaller for a thinner look and lower packaging and transportation costs.

2. The LED chip is located close to the aluminium frame of the LED panel. The heat generated by the chips can easily reach the front of the panel through the outer frame. The heat dissipation rate will be faster in areas with better air circulation.

3. The LED panel will be robust because of the inclusion of a light guide panel (LGP). The LGP supports the outer frame of the panel light, making the entire LED panel more structurally stable.

However, relatively speaking, there are some cons:

1. The energy efficiency is relatively low. By placing the LED around the LGP and guiding the light downward, the export efficiency is lower than the straight-down type, resulting in the overall energy efficiency not being high.

2. The price of an important part of the LGP is high, resulting in an increase in costs. According to the different lumen requirements of the LED panel, different LGPs need to be configured, and the quality requirements are high.

3. The reliability performance is below expectations. Because of the LGP, reflective ink and reflective film in the side luminous, LED panels are always at a relatively high temperature. Panels are easy to age and turn yellow, reducing the light rate and greatly reducing their life.

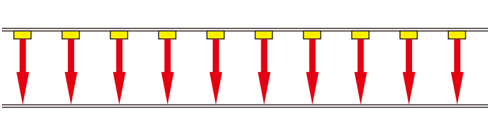

For the backlit LED panel, the luminous structure is like the one below (Figure 2). The light emitted by the LED chip is emitted directly down through the astigmatism of a diffuser plate.

Figure 2

Backlit LED panel lights have greater pros:

1. High energy efficiency. The light emitted by the LED chips is directly irradiated through the diffusion plate, improving the luminaire system's energy efficiency.

2. Reduced Costs: The LGP has been cancelled, resulting in a decrease in the panel's overall cost.

3. The interior space is spacious, and the design offers greater flexibility.

4. The weight of the back-lit LED panel is lighter, and fewer materials can improve the production capacity.

The back-lit LED panel has several cons:

1. The diffusion plate should not be too close to the LED chips to ensure uniformity and avoid glare. If it is too close, a luminous point may be visible on the surface. Consequently, the height of the entire panel light should be high, increasing the thickness of the LED panel.

2. The backlit LED panel has a relatively large gap between the diffusion plate and the back cover. The panel body is mainly supported by the corners of the frame, making it less stable than the edge-lit panel light. The diffusion plate and the back cover are not strong enough to withstand any extrusion, and the panel may get damaged easily during transportation if compressed.